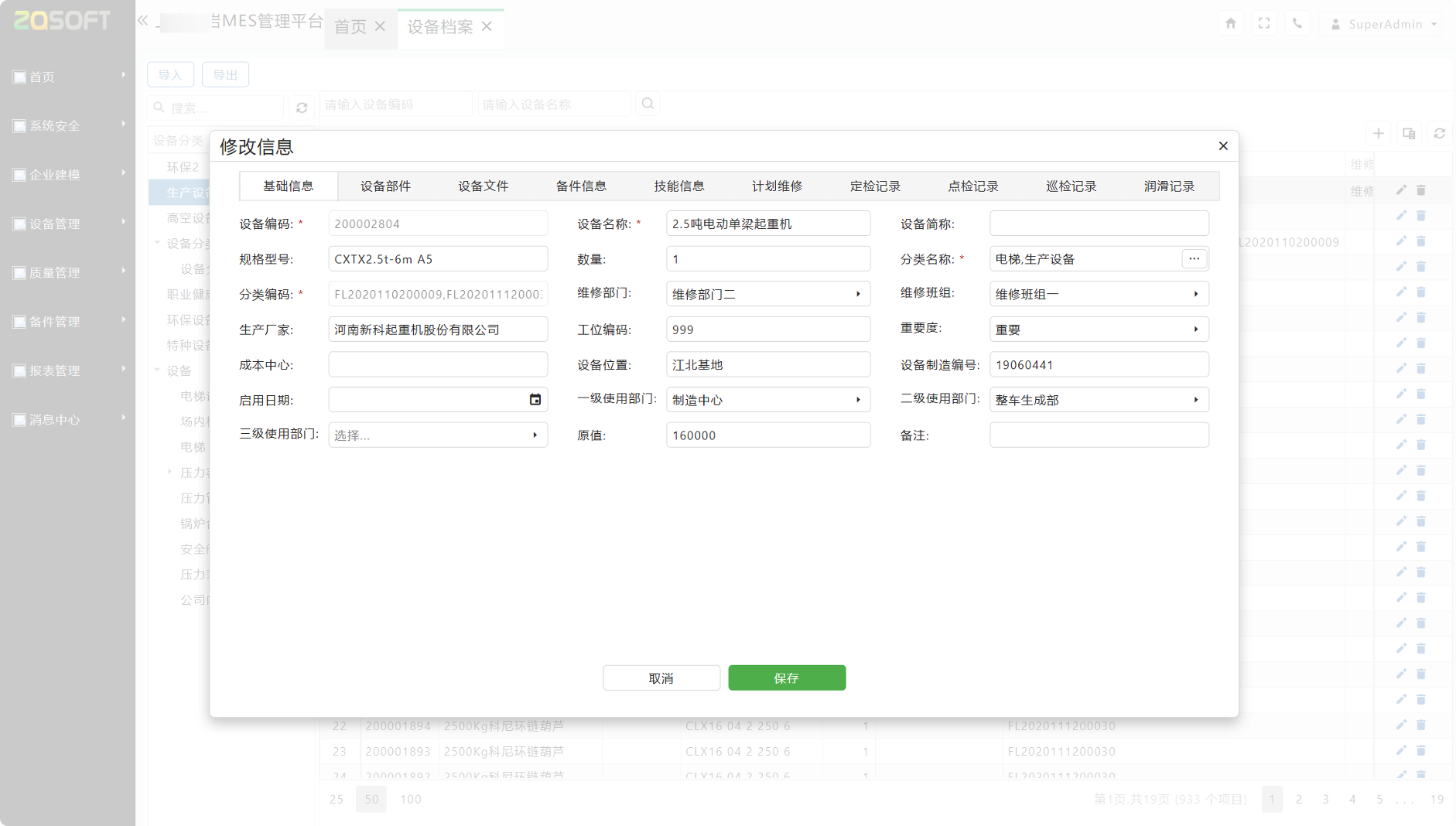

Help create a complete device asset structure tree, with one click access to basic information, BOM structure, operation and maintenance records, spare parts usage, equipment files, operation logs, and more.

Structured and standardized management of spare parts and document information, information configuration engine technology, easy to use, operation configuration, and clear application.

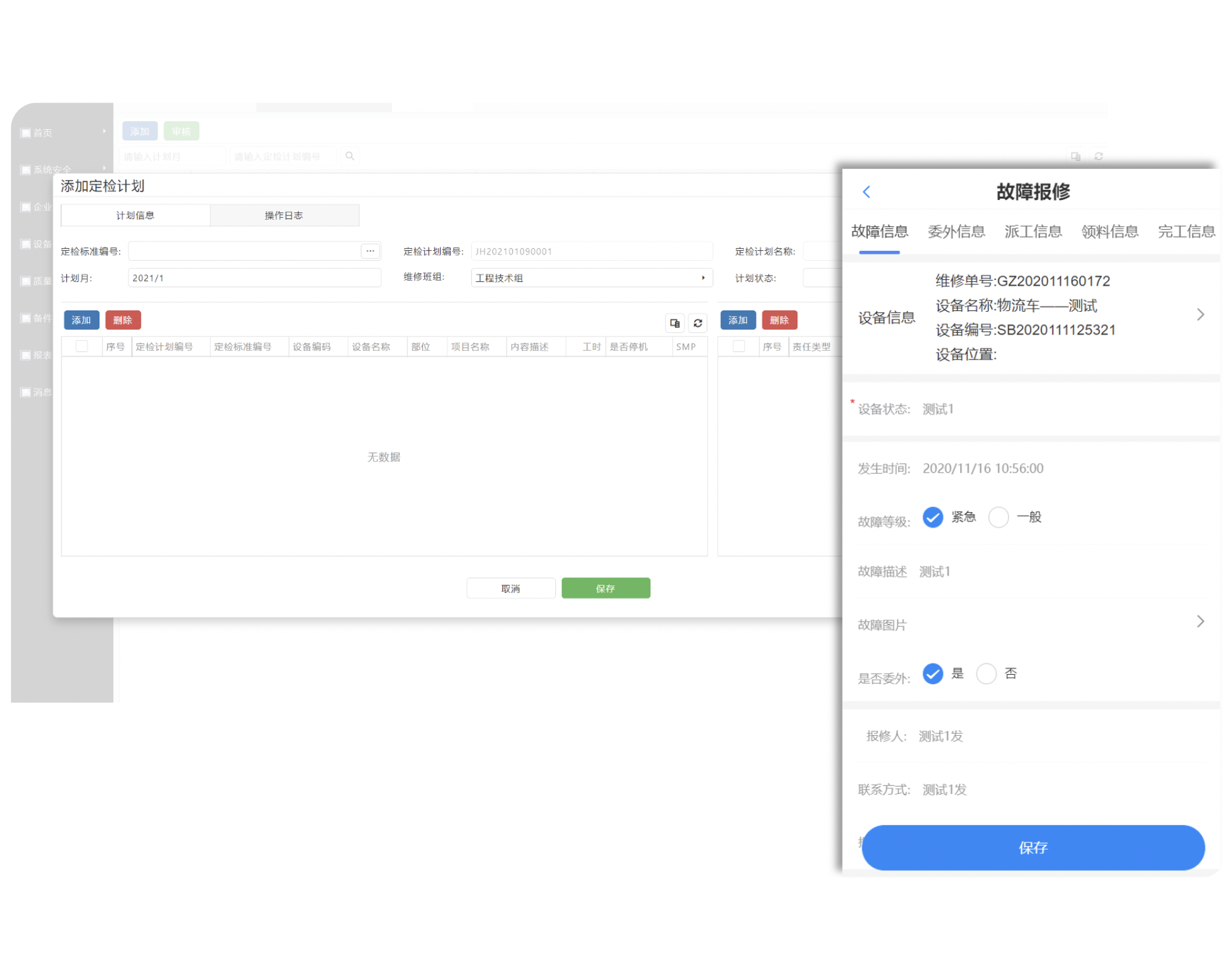

The maintenance team manages the maintenance plan uniformly, and can also manually or automatically release and arrange repair work orders.

The maintenance work order pool gathers all maintenance plans.

Automatically monitor fault information, AI algorithms help you propose preventive maintenance and improvement suggestions.

Using mobile tools to perform on-site maintenance work is flexible and practical.

Build a fault knowledge base to make maintenance smoother and form enterprise knowledge assets.

Collaborate with ZQ-APS to achieve a balance between planned downtime and scheduled maintenance, greatly improving the completion rate of scheduled maintenance and maximizing efficiency.

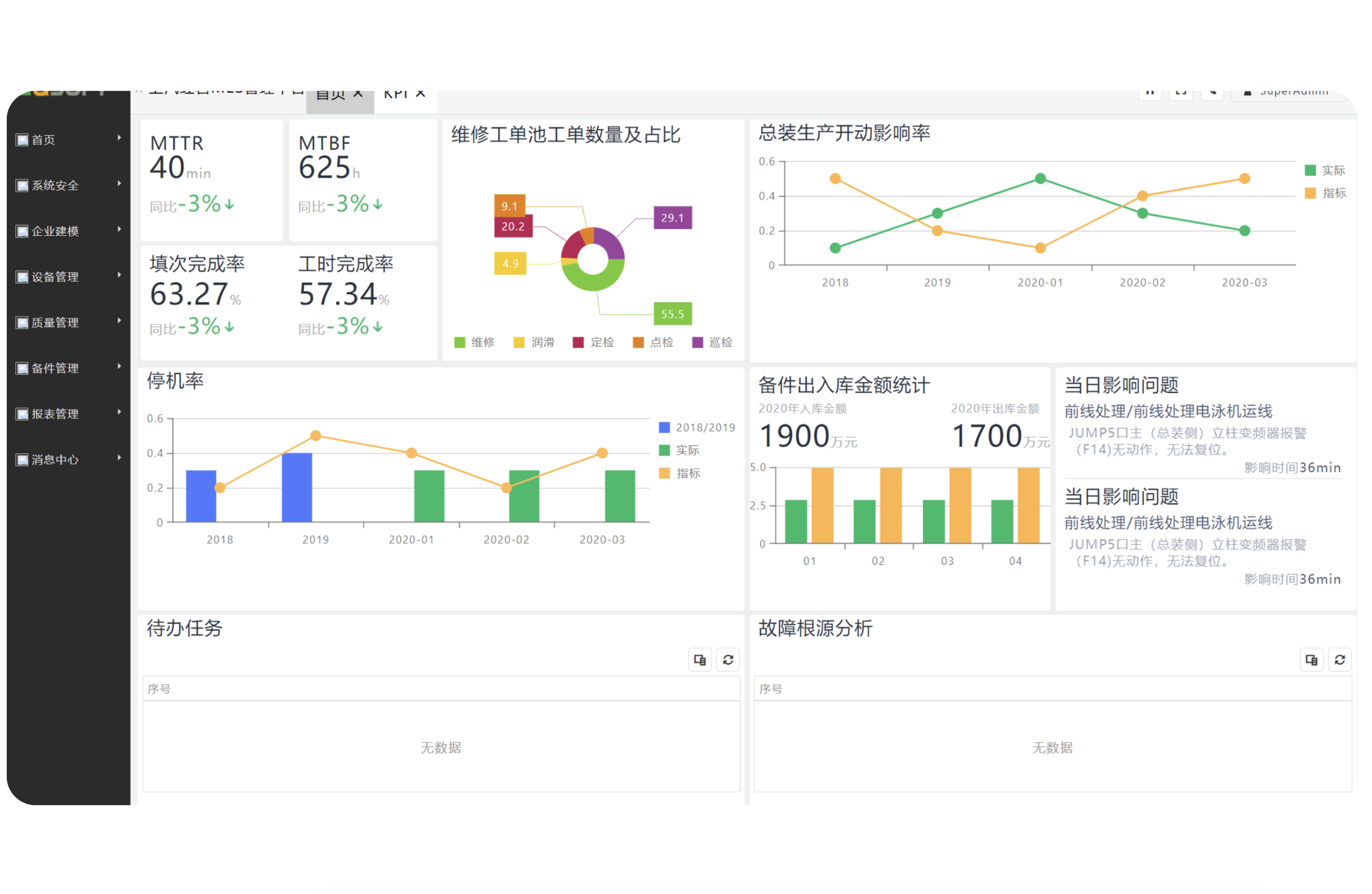

With the help of ZQ-EAM, automatically generate reports and improve the maintenance team's fault analysis capabilities. Comes with graphical reports to deliver to your team.

Combining cockpit management technology, presenting visual data to help visually view key KPI indicators.

Data driven business continues to grow, add value, and upgrade.

Equipment management is centered around operational data analysis, collecting and managing all data and information, combining real-time big data and machine learning to predict and analyze equipment performance, and make optimal decisions.